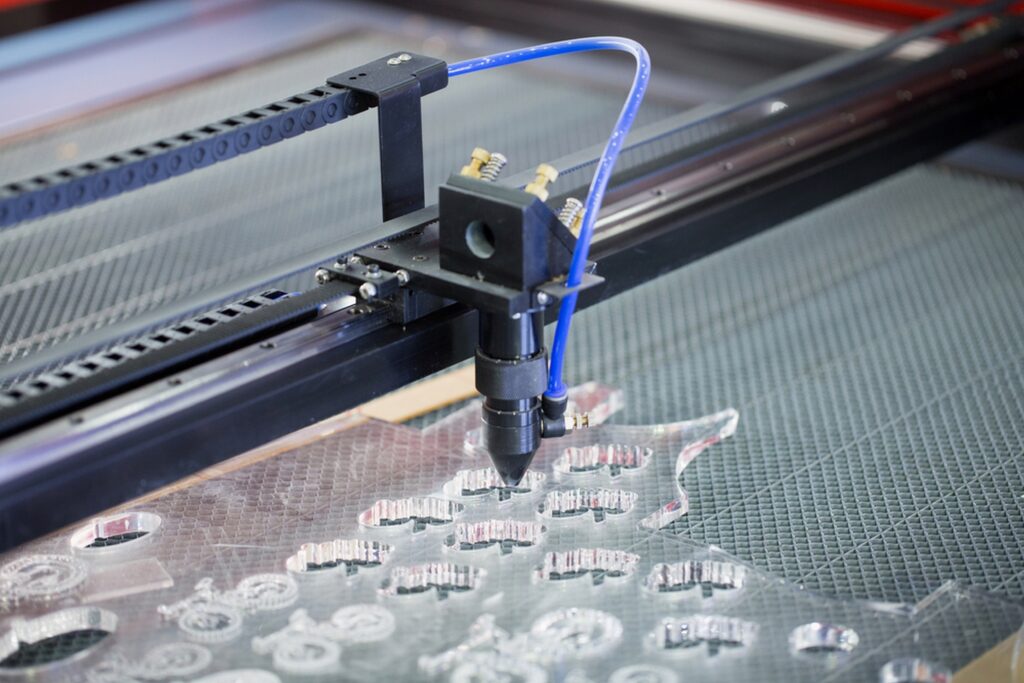

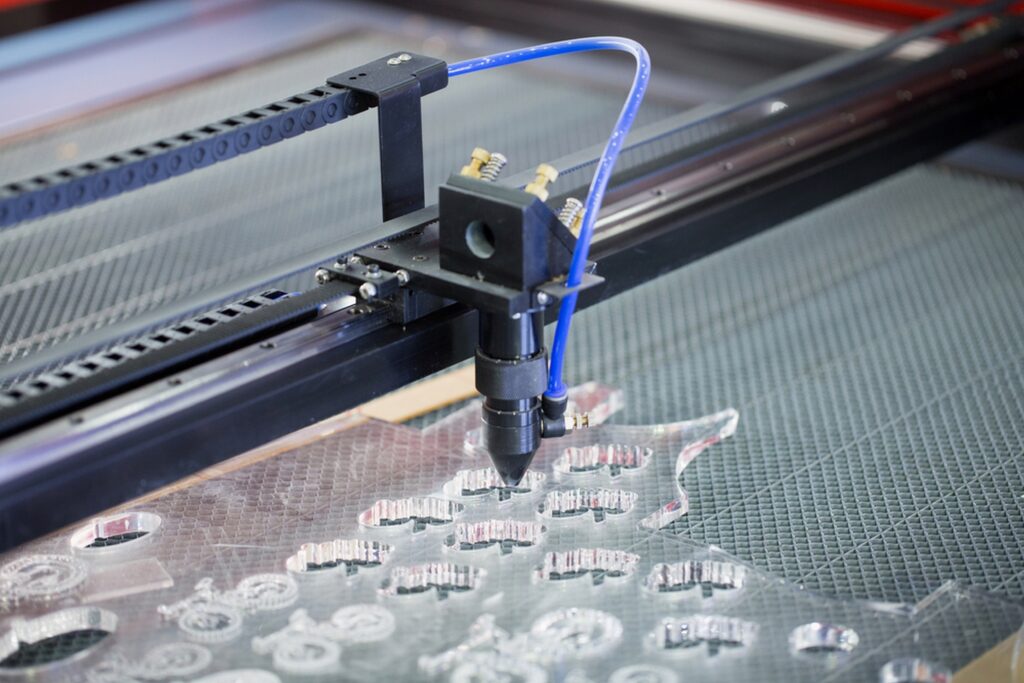

CNC Routing

We feature two production routers for high precision CNC routing with tolerances as close as .002, and we can process sheet/plate up to 240″ long X 10″ thick X 48″ wide.

We feature two production routers for high precision CNC routing with tolerances as close as .002, and we can process sheet/plate up to 240″ long X 10″ thick X 48″ wide.