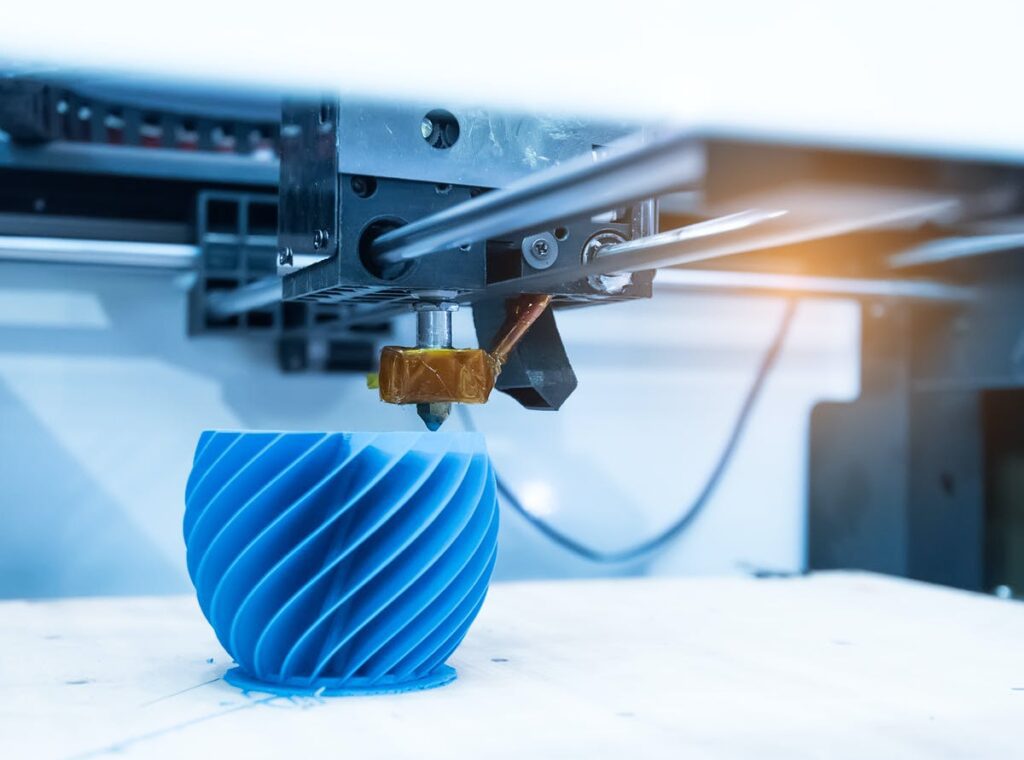

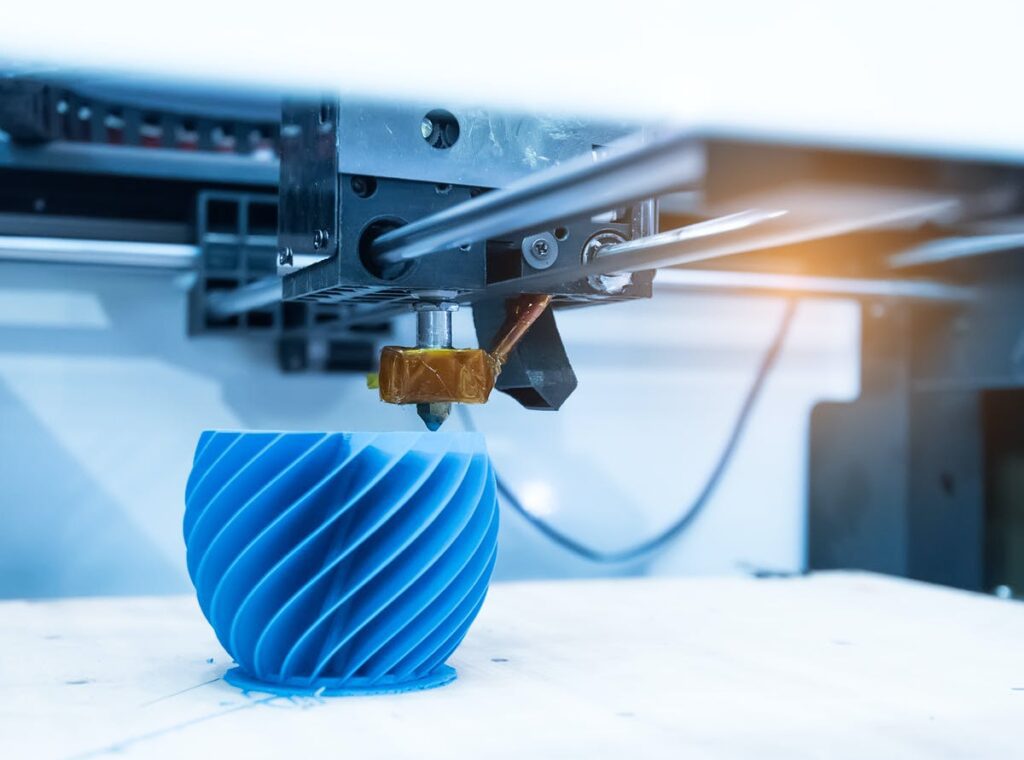

Quick Turn Jobs

We have excellent relationships with our supply chain that delivers the needed material on time. Moreover, Peak has expertise in Rapid Prototype Manufacturing (RPM) for a wide variety of industries.

We have excellent relationships with our supply chain that delivers the needed material on time. Moreover, Peak has expertise in Rapid Prototype Manufacturing (RPM) for a wide variety of industries.